Poly Vinyl Caprolactam Polymerization Using Igracure

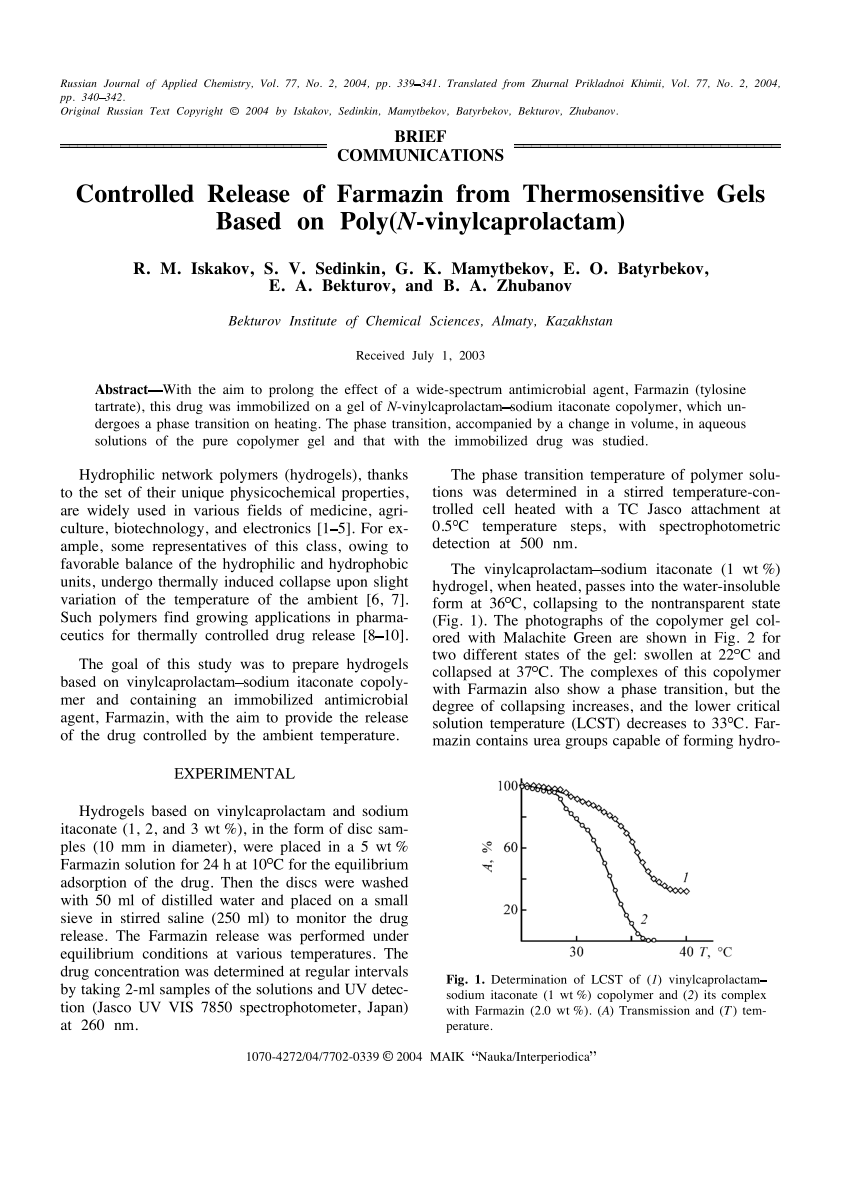

Pnvcl fits the group of poly n vinylamide polymers as it is water soluble a non ionic andwhenatalmost32 c has the lcst value in an aque.

Poly vinyl caprolactam polymerization using igracure. Polymer was characterized by ftir 1 h nmr and 13 c nmr dsc tga and xrd techniques. Gheorghe rusu elena rusu nylon 6 tio 2 composites by in situ anionic ring opening polymerization of ϵ caprolactam. Continuous polycaproamide production has been modeled and shown to give othe than most probable distribution in many cases. Ftir and nmr results showed that polymerization takes place by opening of carbon carbon double bond without any change in the caprolactam ring.

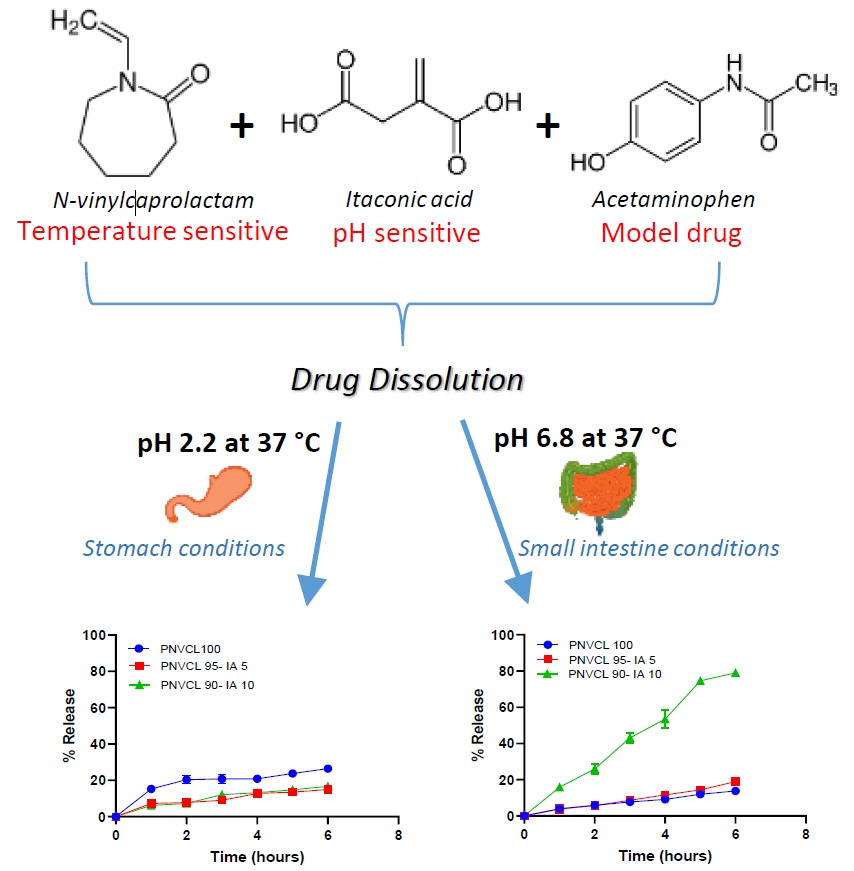

This review highlights the controlled synthesis of pnvcl in different architectures. The synthesized polymers were white powder soluble in water and common organic solvents. The dsc thermogram. Poly n vinyl caprolactam pnvcl undergo phase transition at molecular weight dependent temperature.

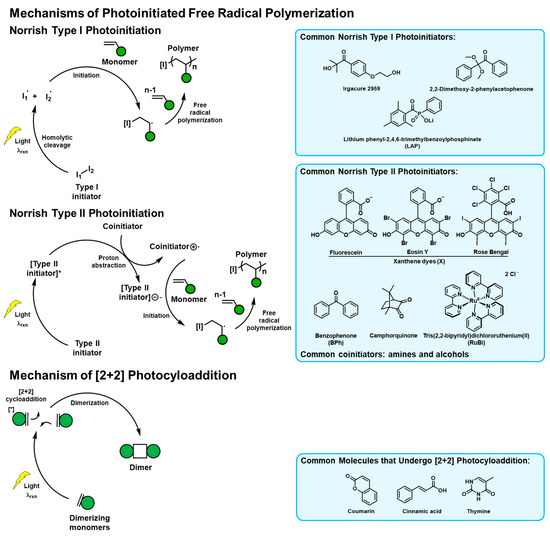

In this study n vinylcaprolactam was polymerized by free radical polymerization at 50 60 and 70 c. Up to now immobilize tio 2 nanoparticle with pnvcl via controlled radical polymerization has not been reported. Atom transfer radical polymerization atrp of n vinylcaprolactam nvcl was studied by uisng ethyl 2 bromoisobutyrate eib as initiator in 1 4 dioxane it led to controlled radical polymerization of nvcl with the molecular weight increased along with the conversion of monomer and a relatively narrow molecular weight distribution could be obtained as determined by gel permeation. Caprolactam the generality reported the most commonly studied ther moresponsive polymer in aqueous solution is poly n vinyl caprolactam pnvcl due to being close to the temper ature after of pnipam.

Chemistry of caprolactam polymerization. Synthesis characterization and properties international journal of polymer analysis and characterization 10 1080 1023666x 2011 622103 16 8 561 583 2011. In this work surface initiate raft polymerization of pnvcl is investigated. A versatile model for ε caprolactam polymerization is presented.

Number average degree of polymerization d p of chain fraction varying from 100 to 10. The activation energy of polymerization was calculated as 108 4 kj mol from the arrhenius plot. A deterministic mathematical basis for obtaining the most probable distribution of molecular weights in batch polymerization is developed.